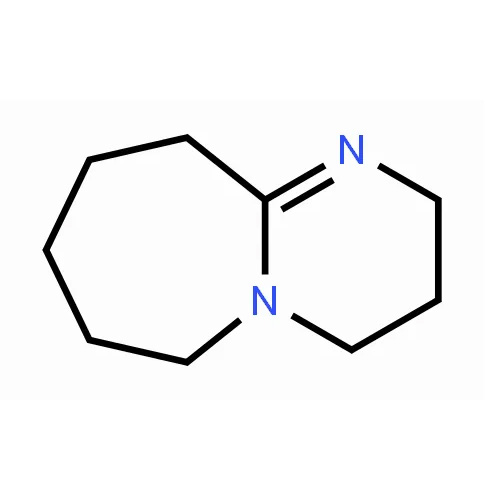

1,8-Diazabicyclo[5.4.0]undec-7-ene CAS 6674-22-2

summary:

1,8-Diazabicycloundecen-7-ene is a colorless to yellowish transparent oily liquid, with relatively low volatility, almost no odor, and alkaline. It is easy to change color when exposed to light, and is hygroscopic and corrosive.

Product name: 1,8-diazabicyclo [5.4.0] undecen-7-ene (DBU)

English name of product: 1,8-Diazabicyclo [5.4.0] undec-7-ene

Package price: 200kg/barrel

Purity specification: 98%

Product category: pharmaceutical raw materials

CAS 6674-22-2 diazo bicyclic catalyst DBU epoxy promoter DBU polyurethane catalyst DBU nitrogen bicyclic

Chinese name: 1,8-diazocycloundecene, diazabicyclo, DBU

English name: 1,8-Diazabicyclo (5.4.0) undec-7-ene

Alternative name: 1,8-diazabicycloundecen-7-ene, CAS 6674-22-2, catalyst DBU, epoxy accelerator DBU, polyurethane catalyst DBU, nitrogen double heterocycle, diazabicyclo

Molecular formula: C9H16N2

Relative molecular weight: 152.2

CAS No.: 6674-22-2

CAS 6674-22-2 diazo bicyclic catalyst DBU epoxy promoter DBU polyurethane catalyst DBU nitrogen bicyclic

CAS 6674-22-2 diazo bicyclic catalyst DBU epoxy promoter DBU polyurethane catalyst DBU nitrogen bicyclic

Physical and chemical properties:

1,8-Diazabicycloundecen-7-ene is a colorless to yellowish transparent oily liquid, with relatively low volatility, almost no odor, and alkaline. It is easy to change color when exposed to light, and is hygroscopic and corrosive.

Relative density: 1.04~1.07

Viscosity (25 ℃): 14mPa. s

Water solubility: soluble in water

Flash point (TCC):>96 ℃

Characteristics and purpose:

1,8-Diazadicycloundecano-7-ene is used as a catalyst in the polyurethane industry. It is a kind of low odor gel catalyst with strong activity, which is mainly used in occasions where strong gel catalysis is required, including formulations containing alicyclic isocyanates or aliphatic isocyanates. Because their activity is not as good as that of aromatic isocyanates, they need strong catalysts;

The activity of 1,8-diazabicycloundecen-7-ene catalyst was significantly enhanced with the increase of temperature. For example, the catalytic rate constants of DBU for isocyanate alcohol and isocyanate water reactions at 70 ℃ were 67 and 35 times as high as those at 25 ℃, respectively, while the catalytic activity of the commonly used bicyclic tertiary amine catalyst triethylenediamine was increased to 5 and 6 times as high as that at 25 ℃;

The 1,8-diazabicycloundecen-7-ene catalyst can be used in the formulation of whole skin foam, microporous elastomer, hard foam, etc.

DBU is mainly used as an excellent organic base deacidification agent for drug synthesis. It can replace organic bases such as triethylamine, N, N-dimethylbenzene amine, pyridine and quinoline, and is widely used in organic synthesis and semi synthetic antibiotics, with satisfactory results in the dehydrohalogenation reaction. It is widely used in the production of cephalosporin semi synthetic antibiotics, such as ammonia and dichloroethane react to form piperazine in the presence of DBU. It can also be used as hardener of epoxy resin, rust inhibitor, high corrosion inhibitor and catalyst for other chemical reactions.

Application of DBU to epoxy resin DBU hardly reacts with epoxy resin in the range of room temperature to 40 ℃, but can make epoxy resin gel in 15min when the temperature rises to 100 ℃. DBU on epoxy resin is mainly used as curing accelerator of epoxy resin for packaging of integrated circuits and electronic components. When used in the form of DBU salt, the DBU is heated during packaging, and the DBU is dissociated to promote curing.

The combination of DBU and linear phenolic resin is a light yellow solid, which changes the disadvantage that DBU is easy to hydrolyze in wet environment. Therefore, the epoxy molding compound for IC packaging composed of it has good moisture and heat resistance and high pressure cooking performance.

Storage and transportation:

It shall be sealed and stored in a dry, cool and ventilated warehouse

packing:

200KG/barrel storage: It is recommended to store in a dry and cool area with proper ventilation. Please fasten the package cover as soon as possible after the original packaging, so as to prevent the mixing of other substances such as water and affect the product performance. Do not breathe dust and avoid skin and mucous membrane contact. Smoking, eating and drinking are prohibited in the workplace. After work, take a shower and change clothes. Store contaminated clothes separately and reuse them after washing. Keep good hygiene habits.

![1-8-Diazabicyclo[5.4.0]undec-7-ene,DBU catalyst,CAS 6674-22-2](https://www.dbuchem.com/wp-content/uploads/2022/10/logo2.png)